Automated Portable Hammering Machine

Hammering is the most widely

used industrial as well as construction activity. Hammering or screws, metal

sheets, parts etc requires a lot of time and effort. So here we propose an

automated hammering system that allows for fully automatic hammering process.

This allows for accurate, fast and automated hammering wherever and whenever

needed using a 12V battery. The person just needs to insert workpeice and start

the hammering machine. This machine can be used for automatic hammering work as

and when needed. We here use a dc motor in order to move the hammer. The DC

motor consists of a pulley attached to it which is connected to a larger pulley

for efficient power transfer and to increase torque. This large pulley is

connected to a shaft that has a connecting rod attached to it. This rod is used

to achieve lateral motion from the spinning shaft. We now connect the other end

of hammer to this connecting rod through a mid swinging arrangement in order to

achieve desired hammer motion with enough torque. We now use a suitable bed

where workpeice can be placed.

The

vibration characteristics of the machine structure during the machining

process. In this article, an optimization of experimental modal analysis

will be presented. The classical measurement chain to perform a modal analysis

is always based upon the principle of excitation, signal transmission,

signal detection, and signal analysis of results. The conventional method,

wherein the excitation is effected by a modal hammer and

the signal detection is done by an acceleration sensor, is now replaced by a

process in which excitation is achieved via an automated modal pendulum

and the signal detection by means of laser or acceleration. Within the framework

of this research, there are two key elements that will be

discussed in detail. The first element includes the motivation for the

development of the pendulum and the aspired improvements of the new

model. A prototype is tested and its performance is valuated. The second key

element represents an experimental analysis of the performance,

including a comparison between the conventional modal hammer and the developed

modal pendulum. Here it should be shown that

the repeatability of the hammer strikes of the pendulum is significantly higher

than that of the conventional hammer. In addition, the adjustability

of the force excitation is to be ensured.

The

main goal of the project is to develop an automated modal hammer in order to characterize

dynamic behavior of a milling machine and workpiece. In milling,

machine tool vibration and workpiece wall vibration plays an important role concerning

both workpiece surface

quality and tool durability. The undesirable motion, which is often referred to as chatter,

can result in wavy surfaces on the workpiece, inaccurate dimensions, and

excessive toolwear. In order to decrease chatter and machine the workpiece in the stable

zone, a modal analysis of the machine can beperformed. For the impact testing,

a modal impact hammer can be used. With the aid of impact testing, the dynamic

behavior of the milling

machine can be characterized. Moreover, when the results of the impact test are simulated,

stability charts for the machine and workpiece can be plotted. However,

in order to achieve

precise results from impact testing one should minimize every possible source of

error. Although modal impact

hammer measurements are quick, easy and inexpensive,there are several significant

challenges to overcome when striving for an “adequate linear estimate”

of the structural dynamic

model.

Firstly,

it is difficult to control either the force level or location

of the excitation point. The input force and the excitation

point can differ from measurement to measurement. Therefore,

the impact usually cannot be exactly replicated. Changes

in the input force and excitation point location mainly depend

on the skills of the operator.

Another

important problem which should be minimized is a phenomenon

known as “double hit”. Ideally, when a structure is

struck, the impact should consist of a single contact in order to

ensure clean data. However, because the impact can occur so quickly,

the structure may vibrate fast enough to hit the hammer

again before the user pulls it away. This results in a double

hit (or more) [7]. Double hits decrease the quality of the Frequency

Response Functions. Minimizing the number of double

hits sometimes takes a bit of practice with operator’s technique,

and less dexterous operators may never be able to achieve

single hits.

Due

to the problems mentioned above, it is not easy to obtain

reliable results from manual impact testing. The reasons behind

the idea of developing an automated modal hammer can be

simply summarized as:

I.

to increase the repeatability of the process,

II.

to obtain a single hit in every trial,

III.

to have adjustable force

IV.

to reduce the manual effort associated with the repeatability

of the process,

V.

to reduce time and cost (high repeatability and no double

hits),

VI.

to achieve an operator-independent process,

VII.

to improve data quality for the simulation software,

The

automated hammer developed for this project should meet

the objectives mentioned above.

Components

- Pulleys

- Rubber

Belt

- Shaft

- DC Motor

- Hammer

- Mounts

& Fixtures

- Supporting

Frame

- Joints

& Screws

Development

Development of an automated modal hammer in the Institute of Machining Technology was started

before this project commenced. However, the

existing design couldn’t meet the

requirements fully. Therefore, some changes to the existing design have been made and the

automated modal impact

hammer has been finished in order to meet the requirements listed above.

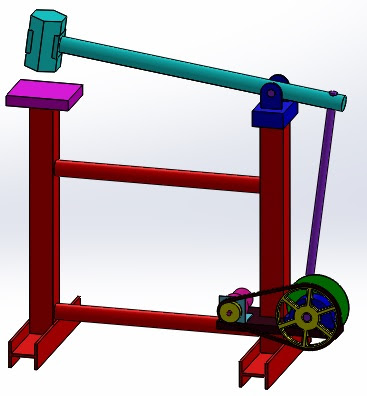

Fig. 1. Design of the general purpose

automated impact hammer

3D modeling software was used in the development of the automated modal impact hammer, allowing

changes to the design to be made quickly and easily.

The model was then animated

for the purpose of kinematic testing and refinement. An automated modal hammer based on the refined

design was produced and used in experiments for

the purpose of validation.

Firstly, one general purpose hammer was designed and then some modifications were made to it in order

facilitate its use

with the 3 axis milling machine. Figure 1 shows the design of the general purpose automated impact hammer,

which can be used for wide range of different

workpieces or different machines. As

can be seen in Fig. 1, there are four main groups of

elements in the design of the automated impact hammer, namely: main

body, driver cam, hammer and stopper. The details relating to each group of the design are

outlined in the following

sections.

The Driver

Group

The driver cam group consists of an electric motor, a cam, a connection rod, a motor coupling, a motor

flange, a ball bearing and two

joints. It is connected to the main body via the bottom joint. Figure 2 shows elements of the driver

cam group.

This group of elements gives motion to the hammer needed to produce the required excitation force

pulse. In this project, a 24V DC electric motor is used. The electric

motor produces the required

rotary motion, which is transferred to the cam mechanism via the connection rod and coupling. The cam mechanism consists of two moving

elements, the cam and the follower. The cam has a

curved outline, which, by its

rotation, causes the follower to move in a specified fashion.

Fig. 2. Elements of the driver cam

group

The Hammer

Group

The hammer group of the automated impact

hammer works like a pendulum. It is connected the

body with its joints. It consists of

a cam follower, connection rods, a ball bearing, a bearing housing, a spring, a hammer housing

and a hammer. Figure 3 illustrates the elements of

the hammer group. The hammer

group of the automated impact hammer works like a pendulum. It is connected the body with

its joints. It consists of a cam follower, connection

rods, a ball bearing, a bearing

housing, a spring, a hammer housing and a hammer. Figure 3 illustrates the elements of the

hammer group.

The hammer group is connected to the main body

with its joints. It works like a pendulum. The cam

follower follows the predetermined

path on the cam untill the tip of the cam. During this motion, the hammer group stores potential

energy against gravity. When the follower finishes

its predetermined path on the cam,

the potential energy converts to kinetic energy and the hammer hits the target

structure. Table 1 shows the motion cycle

of the hammer. The magnitude of the impact is

basically determined by the mass of the

hammer head and the velocity with which it is moving when it hits the structure. This is due

to the concept of linear

momentum, which is defined as mass times velocity. The linear impulse is equal to the incremental

change in the linear momentum.

Fig. 3. Elements of the hammer group

Table 1. Motion cycle of the automated

impact hammer.

Automated

Modal Impact Hammer

The

aim of developing an automated modal impact hammer was

to use it to characterize the dynamic behavior of machines, workpieces

and tools. The designed hammer can be

Fig.

4. a) Dimensions of the automated modal impact hammer relative to the

milling

machine

Fig.

4. b) Experiments with an unusual tool attached milling machine.

used with wide range of these. However, it has

some disadvantages

related to the compactness of its design. It uses gravity in order to create excitation force on

the structure. Therefore,

it can only be used vertically. It is not possible to use it in other orientations. Also, there must

be enough space in

front of the target structure in order to clamp the automated impact hammer.

The designed automated modal impact hammer has

been tested with

different workpieces to meet the objectives of the project. However, it couldn’t be used with the Three

Axis Milling

Machine. The reason for the problem was the dimension of the automated modal impact hammer

and the milling

machine. It could only be used with an unusually long tool attached to the milling machine. Figure 4

shows the dimensions

of the automated modal impact hammer relative to the milling machine and the measurement with

the unusual tool attached

to the milling machine. According

to 3D drawings of the milling machine, some modifications were made to the automated modal

impact hammer.

Figure 5 shows the 3D model of the modified automated modal impact hammer and the milling machine’s spindle.

The same principles have been used with the

modified automated

modal impact hammer in order to achieve the objectives stated above. Only geometrical

changes have been made,

mainly to the driver cam group. Firstly, the main body was tilted 45° with the

aid of clamping

devices. The hammer group works like a pendulum. Due to the required motion of the hammer group

in an inclined configuration,

the upper profile of the main body group was obstructing the motion of the hammer group.

Therefore, a 45° connection

part was assembled to the driver cam group in order to increase the hammer's clearance.

Take a look at those videos:

Refferences: Brüggemann, T., D. Biermann, and A. Zabel. "Development of an automatic modal pendulum for the measurement of frequency responses for the calculation of stability charts." Procedia CIRP 33 (2015): 587-592.

Comments

Post a Comment